Every device and system, including software and configuration should perform reliably to its optimum level. Cotmac's analysis has assisted organizations in assessing applications and helped customers to improve timeliness, accuracy, and stability.

Cotmac’s knowledge and experience has enabled many OEMs and end users to increase performance of their green and brown field projects and R&D processes. Cotmac's control system engineering study focuses on the analysis and design of control systems.

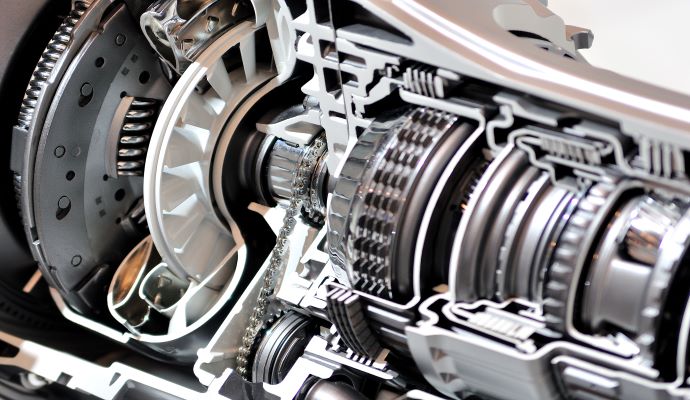

Cotmac study methods imply right from selection of the parts by describing the project on paper with as many details as possible. Identifying requirements during Study takes into consideration the expansion possibilities and the potential future. A lot of detail goes into building a control system and there are a lot of small components such as terminal blocks, labels, jumpers, different gauges and colors of wire and so on and so forth. We make this process a simple and seamless work so that it makes the project move up smoothly.

At this point, it is not clear how conservative designs may need to be to prevent the failures. In this stage, however, we do not focus on design conservatism, but rather on elucidating how process and equipment designs relate to success or failure. Whether it be SISO or MIMO we have legacy expertise and have delivered more than 10K+ projects. Our expertise in understanding your needs gives us the advantage of being the subject matter expert (SME) in controls and how it may impact performance.

Sample Study topics/ objectives include:

- Control panels Requirement

- E-House structures

- IoT Readiness & upgradation

- Improvement of Plant performance

- R&D Test and trail

- Sustainability assistance