Cotmac’s Competence

Turnkey Projects

New Technologies

Customers face the challenge of choosing the right solution, given the evolving nature of technology.

Cotmac’s consultants work closely with customers to understand their objectives and deploy appropriate technology, keeping in mind the long term needs of customers.

Our robust framework and methodology goes beyond cost savings and efficiency enhancements by taking a long-term view of control systems and its management.

As a key player in Industry 4.0, we understand the interplay of communication with machines and data collection for analytics.

Diverse experience helps us to integrate various platforms on the same level. We understand all industrial protocols and gateways required for data exchange between various systems.

We provide complete solutions to our customers and handle projects as a single entity. We can execute the project at any location for the customer.

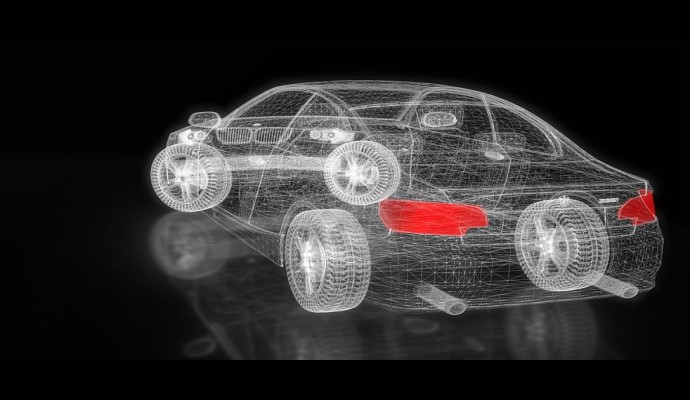

We have helped process industries with data analytics and worked with Automotive industries to integrate various field devices on profinet and Ethernet IP platforms.

We can write programs to communicate with third-party devices.

We understand that improving efficiency of the current system involves implementing new technologies and smooth integration with legacy systems, if any. A complete system migration may also be contemplated, depending on customer requirements.

Our work includes:

Wastewater treatment plant automation using Siemens DCS with remote ET200M I/O modules connected via optical link on Profibus protocol.

Read More

Automation of wastewater treatment plant with Biological Nutrient Removal (BNR) process using Siemens S7-300 PLC system in the US market.

Read More

A CO2 extraction & purification segment of a carbonated soft drinks manufacturer wanted to ensure high productivity.

Read More

Leading automotive manufacturer achieved significant cost savings through productivity enhancements by upgrading engine shop line through automation with poka-yoke system.

Read More

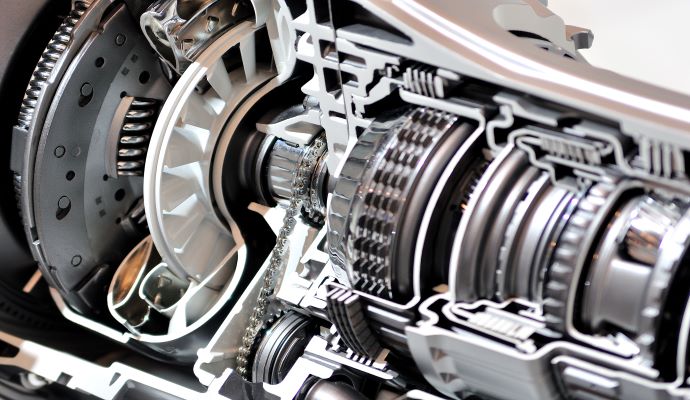

Developed a comprehensive PLC control system for test rigs for gearbox systems which required high speed and high torque capabilities.

Read More

Multi-utility vehicle line capacity expansion and automation of new fixtures for dash line, using Siemens fail safe system.

Read More

System integration services for automation of sand as well as the moulding plant, and creation of a centralized management system.

Read More

Improving operational effectiveness by upgrading the automated assembly line by installing an RFID system to track parts throughout the line.

Read More

Automation of 30MW Power Plant with two boilers using Siemens DCS control system to increase productivity and drive cost savings.

Read More

Energy management system for an agricultural waste biogas plant to reduce operating costs for the entire life cycle of plant.

Read More

Automation of CO2 extraction & purification process in a carbonated soft drinks manufacturing plant using S88 based modular programming implementation.

Read More

Automation in a distillery manufacturer was aimed at reducing manual intervention to minimize production time, molasses wastage and manual error.

Read More

Engineering, development and commissioning of a brewery plant in U.S., to improve brew length and maximum brew per day.

Read More

100 TPD milk powder plant automation to ensure standardized milk quality, enhance production capacity and reduce losses due to perishability.

Read More

From studying the requirements to commissioning of the control system for rice mill machinery with conveyors, elevators, and storage tanks.

Read More

Deep freezer automation across different sections in the plant to keep the seafood fresh and ready to sell, using Allen Bradley.

Read More

Automation of vegetable oil treatment plant for better productivity and consistent product quality, using S7-300 / S7-400/ PCS7 based architecture.

Read More

Automation of gas mixing plant in a steel line to reduce manpower and operation cost by creating a centralized operation system.

Read More