Background

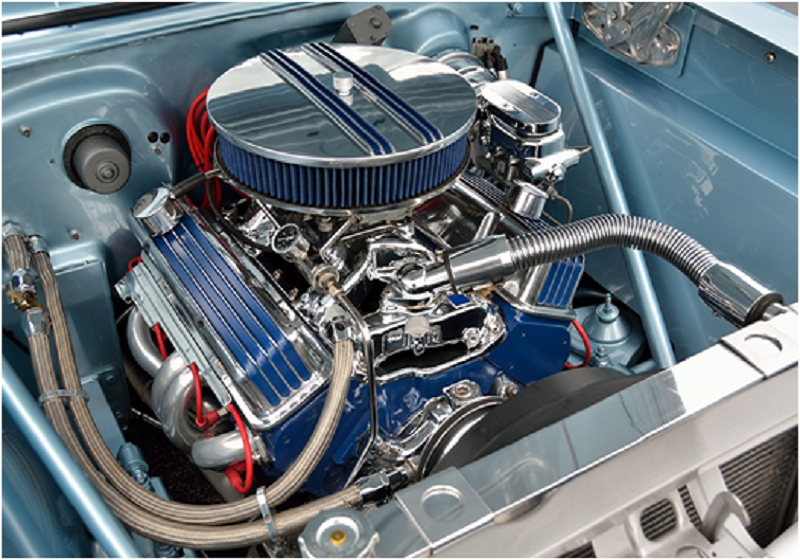

Our customer came to us with an ambitious plan to upgrade their engine shop to add significant automation with built in mistake proofing. They were seeking significant cost reductions and quality improvements by improving their processes and automating them.

Approach

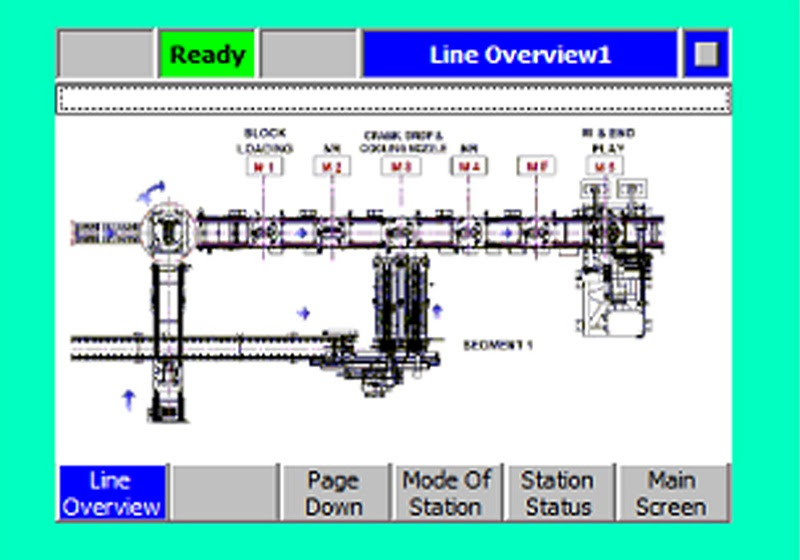

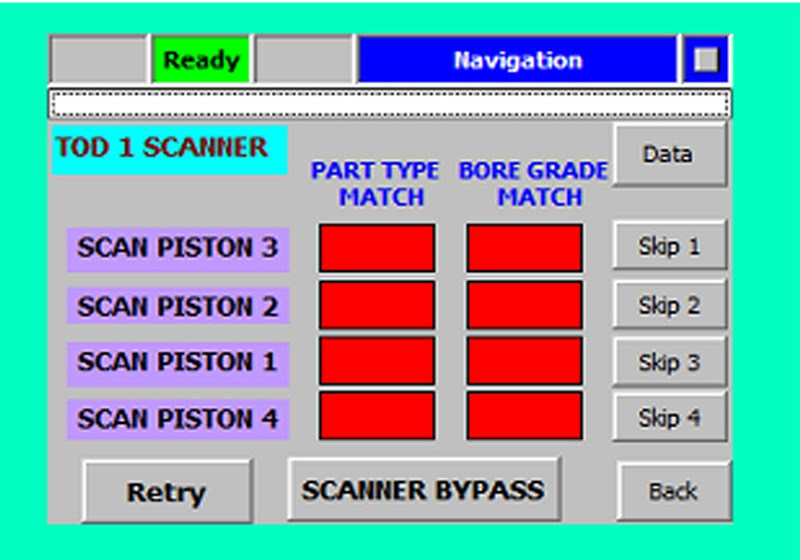

We helped with the design of their newly automated line, adding poke yoke designs to prevent mistakes from being made.

Implementation

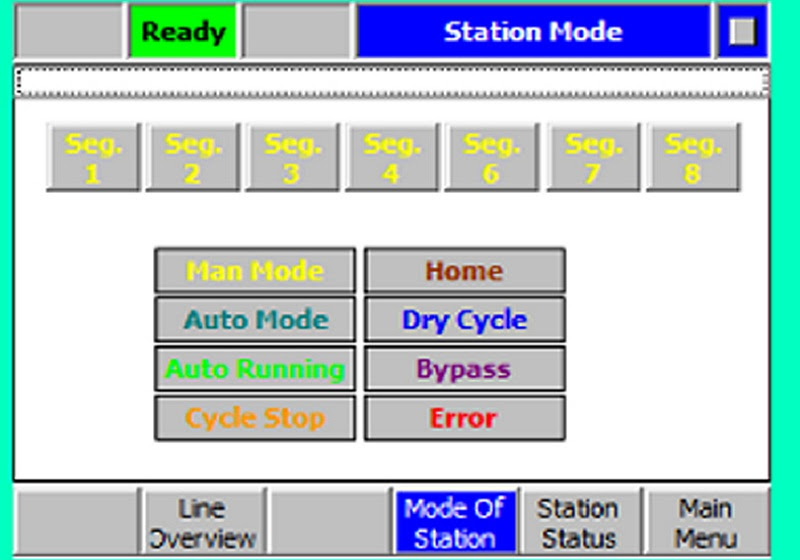

We implemented Simatic Manager and SimaticWincc Flexible 2008 SP3, Simodrive (Profibus DP and Profinet Communication). We used S7 400 PLC systems at each station to help implement the mistake proofing designs.

Outcome

Our customer achieved significant productivity improvements because of the automated processes and improved quality due to our design. They were able to produce more with less people. Our designs and implementation also allowed them an easier path to upgrading their systems in the future with minimum shutdown time.